Case study: Development of IoT home alarm hub

Project overview:

Startup from the UK, saw an opportunity to meet the user’s needs and position in premium segment on the security systems market.

After looking for ready-made and OEM solutions, the client did not find appropriate product that would meet the requirements.

This means that design of custom solutions was the way to go.

One of the main criteria was that the system is certified as grade II alarm system with possibility to connect to police station monitoring center.

The approach:

In order for business model to be viable, the total manufacturing and BOM costs limit has been set by the client.

Our team had to create selection matrix for all of the main components and carefully evaluate product performance vs cost.

One of the main criteria for business model was to achieve long range of wireless signal on sensors and external warning device, that is enough to cover average 5 bedroom, 3 floors town house in the UK, without the need for additional signal repeaters.

To select the best wireless sensor technology for this use, our team had to perform calculation of link budget and perform module performance testing for several different technologies.

Additional challenge was a requirement that the hub should be compatible with other devices on the market, such as smart lights, sensors, etc.

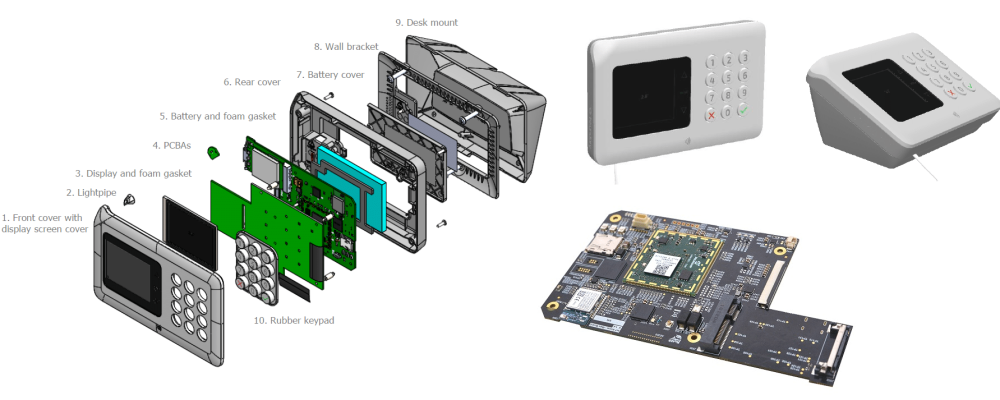

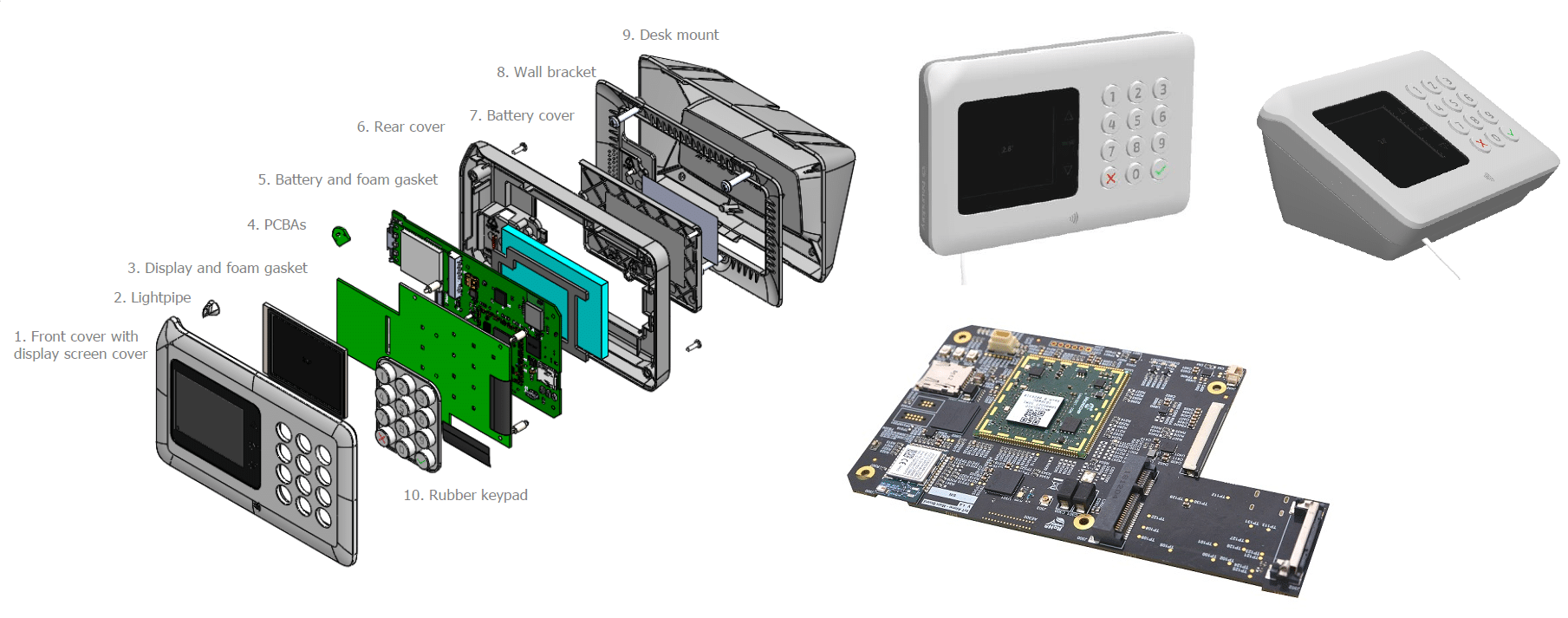

Several wireless technologies has been combined into single hub device: Wi-Fi, Bluetooth, NFC, Z-wave, GSM (4G, 2G).

Considering size of enclosure, having multiple antennas within small area created significant RF design challenge that required design of custom RF sections and support from RF expert partner.

Hub is running on embedded Linux. Integrates Cortex A5 mpu @500Mhz, Z-Wave, 16GB eMMC, TFT touch screen, battery charger & monitor, PCIe for GSM (4G/2G), Wi-Fi, Bluetooth, NFC reader, LED driver, keypad.

IoT embedded security features have been implemented both in hardware and firmware.

Our team did:

– Hardware design and verification

– Creating custom embedded Linux build

– Hub Firmware development

– Pre-compliance functional testing according to Grade II alarm standards

– Testing in environmental chamber (dry heat, cold, temp. change, damp heat-steady state, damp heat-cyclic)

– Manufacturing support