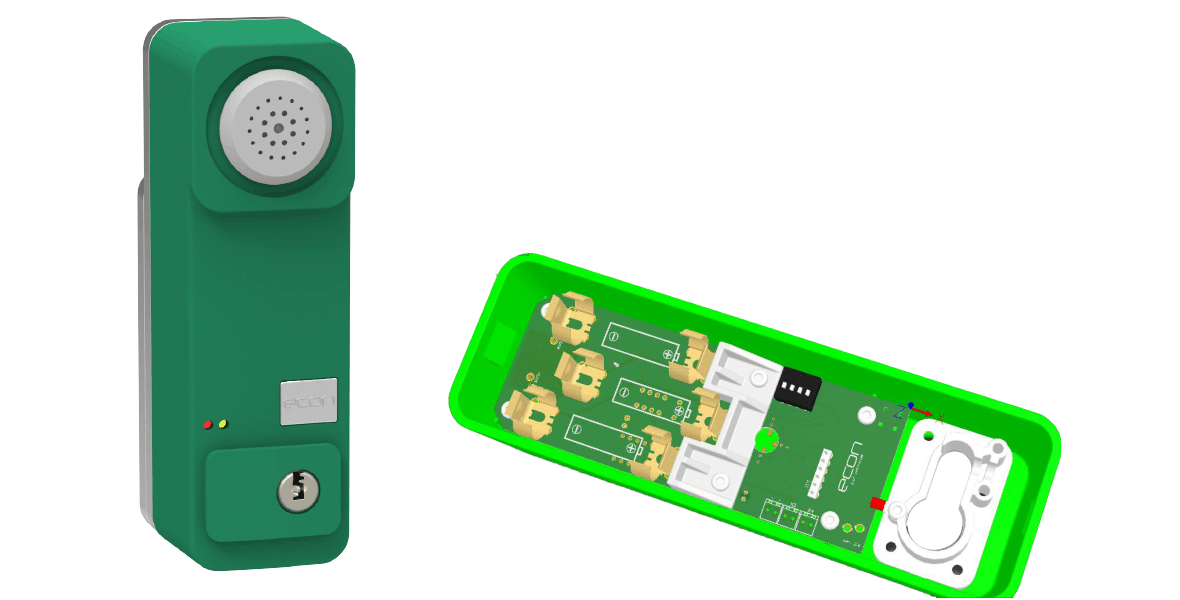

Case study: Alarm device for emergency exit

Client had an existing product on the market that was originally developed by another company.

The product had high failure rates in the field due to poor hardware design.

The battery life was 25% shorter than expected.

Firmware was unstable, causing unpredictable alarm triggering and issues during disarm process.

Product was difficult to produce, causing low manufacturing yield, thus costly failure diagnostics and re-work.

ARS team did the following:

– Complete redesign of PCB.

– Optimizing PCB design for multiple product variants, thus reducing manufacturing costs

– Optimizing BOM and reducing component cost by more than 13%

– Development of completely new and stable firmware for multiple product variants

– Optimized PCB design and firmware improving battery life from avg. 9 months to more than 24 months

– PCBA manufacturing support

– Certification support and EMC testing

The product is shock-resistant, splash-proof and sabotage-protected (protection class IP67) with alarm siren

volume at least 98dB at a distance of one meter. Tested according to EN1125, EN179, EN1634.