Case study: Development of IoT smart sauna system

Project overview:

The client, Sauna manufacturer from Finland, needed a completely new product, that will enable monitoring and control of sauna via cloud. Intended use of this system is for predictive maintenance, better insight into sauna usage, remote control and remote technical support.

As a manufacturer of special high-end saunas, that are used in commercial spaces like spa centers, reliability and usage data are very important.

Unpredictable failure of sauna can incur financial losses or bad reputation to spa center, so our client wanted to be able to monitor the performance of saunas installed in the field.

Data about usage frequency, internal temperature, stove settings would provide valuable data for future design optimization and potential savings.

On the other hand, monitoring of current consumption on heaters and fans enables to timely predict upcoming failures, before they actually happen.

This enables service technicians to plan part replacement outside regular working hours of spa center, thus avoiding the expensive service interruption.

The approach:

After analysis of project requirements, we have build a quick Proof of Concept (PoC) demo to verify customer’s requirements.

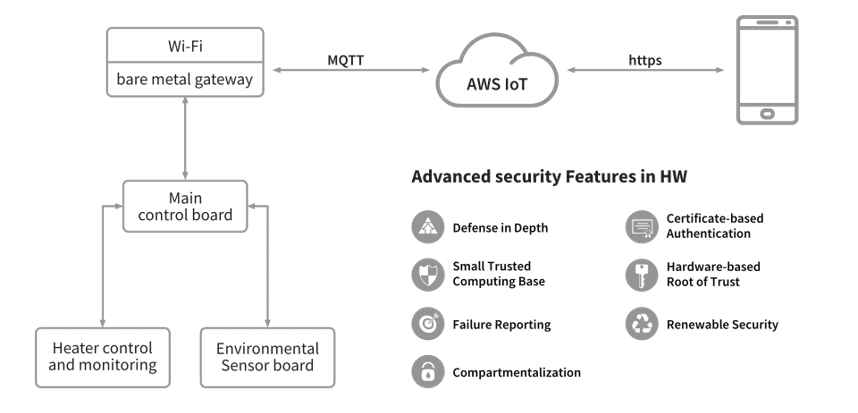

Considering the results from PoC tests in real working environment, we proposed the following architecture for the final system:

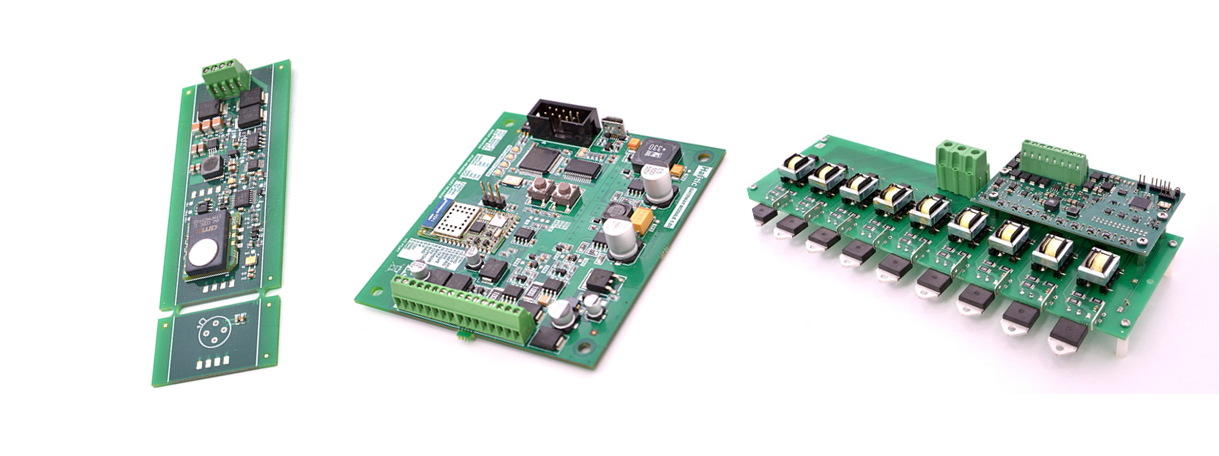

The system includes 4 boards:

– Wi-Fi gateway

– sensor board

– Main control board

– high current heater control board.

Main control board is reading data from sensor board, forwarding information to gateway board which connects to AWS cloud service.

Information about heaters and current consumption is collected from “high current board” and forwarded to the AWS cloud.

Firmware supports over-the-air updates, sauna scheduling, stove fan control and monitoring.

Sensor board includes:

– Air quality sensor

– Humidity and temperature sensor

– Infrared temperature sensor

– Acoustics (noise) sensor

Control board contains isolated inputs and heater control outputs, but also circuitry for monitoring heater current consumption via isolation transformers and current measurement chip.

Our team did the following:

– Hardware design

– Firmware development

– Development of PC software for device configuration

– Integration of device with AWS cloud service

– Development of software for creating and flashing unique AWS certificates

– Manufacturing support